Practical Chemical

Additive Solutions

Contact Mayzo today at 1-800-449-9068.

- Lack of technical resources

- Pressure to achieve immediate return on investment

- Concerns regarding sustainability and risk reduction

- Difficulties managing the supply chain

- Employee turnover and challenges with less experienced employees

Mayzo’s Plus Advantage encompasses a range of features and benefits tailored to meet your needs:

- Ease of doing business

- Extensive product portfolio to cater to diverse requirements

- Dedicated technical support to assist you at every step

- Reliable and timely delivery services

- Commitment to environmental, health, and safety (EHS) sustainability

- Risk reduction, product technology performance, and agility

These advantages aim to provide you with a comprehensive solution that helps overcome challenges and enable success in your businesses, even in challenging times.

Which best describes you?

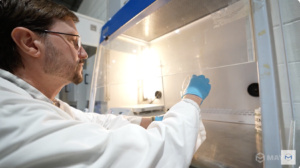

Mayzo’s Custom Additives Program

Designed to solve customer problems related to additive MEASUREMENT, INCORPORATION, EFFICIENCY, and HYGIENE.

We work closely with our customers to uncover and define the most cost-effective, quality-driven solutions. We use a variety of product forming and processing technologies, including blending, granulation, pelletization, and extrusion, to improve additive incorporation of a single product or a formulation containing several different components. We also provide custom-sized packaging options and inclusion bags which can be added directly to the process to eliminate feeding and dosing errors.

Custom Packaging

Mayzo’s Custom Packaging program includes:

- Matching packaging size to manufacturing batch size to eliminate the need to weigh out materials

- Pre-blended additives in solvents or other carriers

- Pre-weighed inclusion bags which are added directly to the process (no weighing, no dust, and no loss of material)

Custom Additive Blends

Mayzo’s Custom Additive Blends Program includes:

- Development of proprietary formulations for specific customer applications

- Product forming of customer’s formulations

- Various product forms: powder and liquid blends, granulation, pelletization, and extrusion

- Pre-compounded products

- Polymer, wax, solvent, and other carriers

- Efficiency solutions

Alternative Forms

- Various product forms powder and liquid blends, granulation, pelletization, and extrusion

- Pre-compounded products polymer, wax, solvent, and other carriers

News / Resources

Welcome to our company news section! Here, you’ll find all the latest updates, developments, and exciting news about our company. From new product launches to important partnerships, we aim to keep you informed about everything happening within our organization.

Stay up-to-date with the latest news by checking back regularly, and feel free to reach out to us if you have any questions or comments.

Thank you for your continued support of our company!

News / Resources

Welcome to our company news section! Here, you’ll find all the latest updates, developments, and exciting news about our company. From new product launches to important partnerships, we aim to keep you informed about everything happening within our organization.

Stay up-to-date with the latest news by checking back regularly, and feel free to reach out to us if you have any questions or comments.

Thank you for your continued support of our company!

Get a Career With Mayzo

Founded over 35 years ago during the early era of economic globalization, Mayzo has become one of the most extensive providers of specialty chemical additive solutions in the United States. Today, Mayzo’s materials are widely used in a growing range of everyday products that consumers rely on. Join us to make a difference in the world and in your career.

Check out our current openings: